Twist-Off Bolts Bolting Method

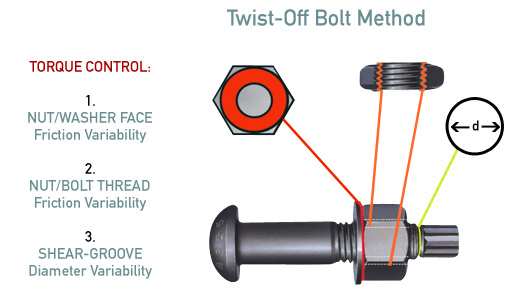

Twist-off-Bolts measure torque which can never accomplish more than measuring the friction generated in the threads and on the nut face. This varies depending on many factors including, but not limited to lubricity of the threads and nut face, and thread tolerances and general thread condition. It is tension that determines the clamp loaded strength of a connection, NOT torque. Most research into torque, under the best conditions of bolt thread tolerances and lubrication is bolt tensions varying by plus or minus 30% at a given torque. Our new DVD includes an excellent documentary on why torque generally fails to accomplish a given measurement of fastener tension. It describes that the "K factor" which is the friction factor is a moving target and cannot be controlled. On construction sites deteriorating conditions are so exacerbated as to render torque measurement pretty well useless.

A recent study, comparing torque installation following EU standard EN 1090-2 for torque tightening bolts with DTIs, most bolts tightened by torque measurement were under tensioned, some by a wide margin. RCSC (USA) code correctly requires so many checks on torque tools and fasteners as to render torque measurement almost impractical. Torque measurement was once completely banned in the RCSC specification in the early 1980s. In TurnaSure's view, that decision was correct.

Solution: Specify TurnaSure DTIs

Our DVD's "Questioning Torque" documentary section includes "Twist-off-Bolts" which also operate as a torque measuring fastener, but the break off part is the pre-set torque measure, but not as precise and an actual torque wrench, which is still not a measurement of tension. Dried out or rusty, or when coated with zinc, these bolts invariably do not provide proper tension. They are not easy to "snug" as when returning to apply more tension the start up "shock" to the system can prematurely break of the end of the bolt.

Solution: "Twist-off-Bolts" can be allowed but specify they are to be used with TurnaSure DTIs. TurnaSure DTIs assembled under the heads prove the needed tension was achieved. Experience proves if more tensioning is required an impact wrench usually works to tension the bolt further, even though they have a button head that cannot be held.

Contact TurnaSure today for more information, availability and quotes.

Contact Us

Contact Us